Founded in 1995, Haomai has developed rapidly with innovation and diversification. Its business covers tire mold, machining, cast steel and cast iron, CNC machine tools, offshore oil and gas equipment, chemical equipment and other fields, with total assets of 20 billion yuan and more than 20,000 employees. It has 1 listed company, 9 high-tech enterprises and 7 overseas companies. Since its inception, Homag has been committed to the research and development and manufacturing of machine tool equipment, and in 2022, Shandong HOMag CNC Machine Tool Co., Ltd. officially sold and debuted. The business covers CNC gold cutting machine tools, laser and EDM machine tools, machine tool accessories, rubber machinery and so on.

Customer pain point:

Solution & Value:

In view of the current situation of PCD tool laser processing, the team of Suzhou Qianzhineng Technology Co., Ltd. proposed an adaptive processing scheme based on in-machine measurement and error compensation technology. Based on in-machine measurement technology, the software detects the welding or clamping errors of the PCD blade, automatically constructs the back tool face and generates the laser machining tool path. Support parametric programming of non-standard tools; Support standard tool template programming; Support chip breaking trough, negative chamfering and other feature processing; Support Huazhong CNC, Heidehan, Siemens and other CNC systems.

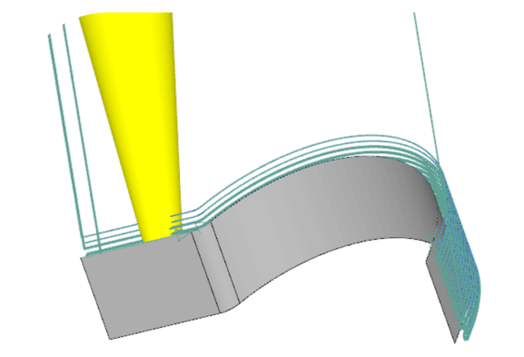

QJCAM.Fit front tool face measurement

Users only need to input DXF graphics, no need for three-dimensional digital modules, you can program operations in the software. The shape of the front cutter face was fitted by measuring the points on the front cutter face.

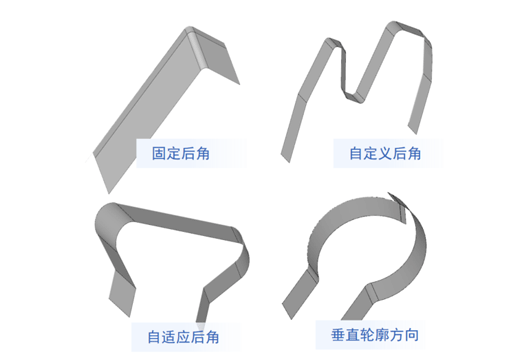

QJCAM.FIT rear cutter face generated

Generate back cutter face according to design requirements and parameter definition, support single and double back Angle mode, can define axle diameter back Angle. It provides four ways to generate the back tool surface: fixed back Angle, custom back Angle, adaptive back Angle and vertical profile, which can meet the needs of various types of tool machining.

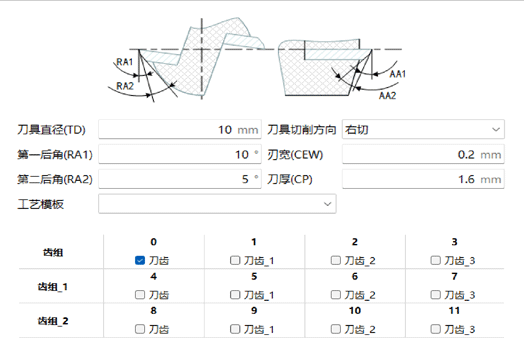

QJCAM.FIT Laser processing process parameter library

The user can establish the process parameters of laser processing into a library to form the solidification of experience. Through the call of the parameter library, the laser machining tool path is mapped to the back tool surface, which greatly reduces the repetitive operation in the programming process and improves the programming efficiency.

QJCAM.FIT can customize the edge, spiral knife template

Can be customized for the user's standard tool template, without importing DXF graphics, through the graphical parameter configuration can complete the construction of the entire project, one click start.