Hunan Automotive Engineering Vocational University is the first public undergraduate vocational college in Hunan Province. The university covers an area of 1592 mu, with 1020 full-time teachers and more than 17500 full-time vocational students. The School of Vehicle Engineering, School of Vehicle Application, School of Mechanical and Electrical Engineering, School of Information Engineering, School of Aeronautical Engineering, School of Navigation Engineering, School of Economics and Management, School of Clothing Art, School of Business and Trade, School of Sergeant Education, School of Marxism and other teaching units, offering 6 full-time undergraduate majors and 43 full-time junior college majors.

Customer pain point:

Solution & Value:

In this school-enterprise cooperation textbook development, Suzhou Qianzhican Technology Co., Ltd. mainly provides a complete set of processing plans and engineering documents for four parts, and completes the program verification and actual processing in the production workshop. In the actual processing process, we cooperated with the shooting team to complete the video shooting of the feeding, clamping, knife setting, processing and other processes, which provided standardized materials for the digital teaching of the school and presented real processing scenarios to students, thus improving their professional knowledge and practical ability.

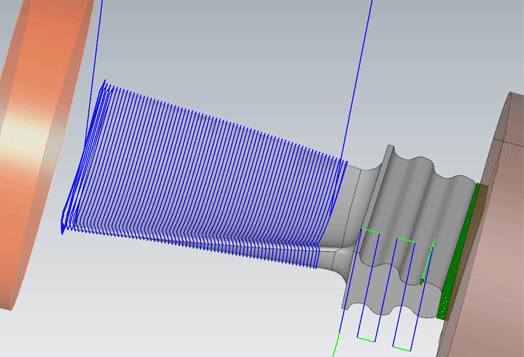

QJCAM.Expert single blade milling

QJCAM.Expert module contains 2~5 axis general milling strategy, compatible with foreign mainstream CAM software logic, rich tool path method, with machine tool simulation function, CAM+ machine tool simulation integration.

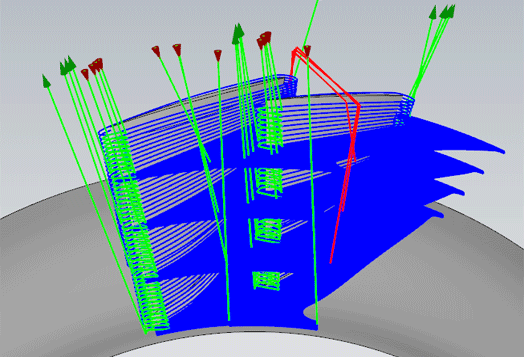

QJCAM.Turbo shunt disk processing

By using the strategies provided by QJCAM.Turbo, such as cycloidal milling, roughing milling, blade finishing, milling finishing and transition corner finishing, the whole disk program was completed, and the whole disk processing was completed on the production site of thousand machines.

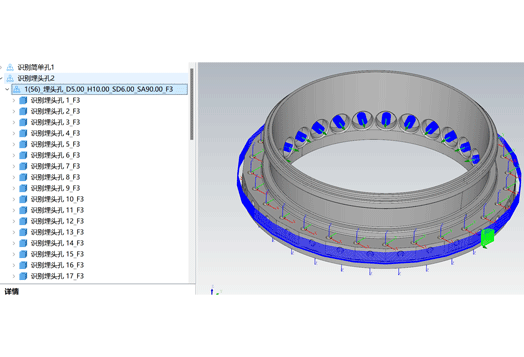

QJCAM.Feature Feature programming

For case parts with many repetitive features, QJCAM.Feature provides feature recognition function to improve programming efficiency and accuracy, and supports features such as holes, slots, bores, and gas film holes. The same characteristics are applied to the process template, and the tool path is generated with one key to achieve process standardization.

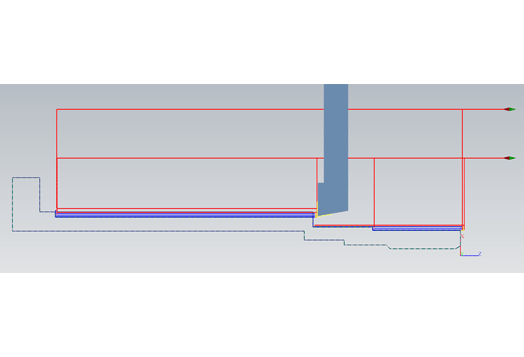

QJCAM.Turning long axis machining

QJCAM.Turning is a CAM software for the whole industry general parts turning programming, with a complete turning tool library and programming strategy, in line with the mainstream programming habits. The full sequence machining of long axis parts is completed by using the functions of fine turning groove, copying turning, dynamic turning and turning thread.