Dongguan Evermi CNC Equipment Technology Co., Ltd. is located in Humen Town, Dongguan City, Guangdong Province, the company was founded in June 2015. Is a research and development, production, sales, service as one of the professional CNC machine tool as the leading manufacturing enterprises, adhere to the "industry to serve the country, help China's high-end manufacturing upgrade" enterprise mission, is committed to "master the core technology, focus on five axis technology, To achieve high-end five-axis CNC equipment "for domestic civil aviation, automotive, medical and other precision processing and successful overall solution." Close mold parts processing field.

Customer pain point:

In the trial production or debugging stage of the first part, the key dimension requirements are measured and guaranteed in the sequence, which requires multiple clamping and disassembly of the parts, which is time-consuming and labor-intensive.Solution & Value:

In view of the above situation, the team of Suzhou Qianzhaineng Technology Co., Ltd. proposed a self-cycle compensation scheme based on in-machine measurement. With QJCAM.Inspection as the platform, based on key technologies such as in-machine measurement, feature size evaluation, and size compensation processing, the purpose of automatic in-machine detection, alarm, analysis of parts error trend and timely correction processing is achieved.

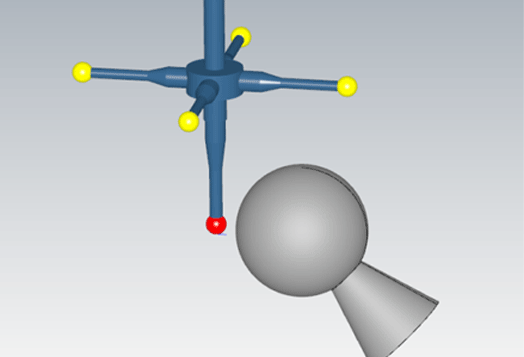

QJCAM.Inspection Probe calibration

QJCAM.Inspection integrates the probe calibration function to calibrate various types of probes by ring gauge or standard ball, obtain the measurement compensation value through data fitting and deviation calculation, and call the compensation data from the compensation list in the subsequent measurement process to improve measurement accuracy.

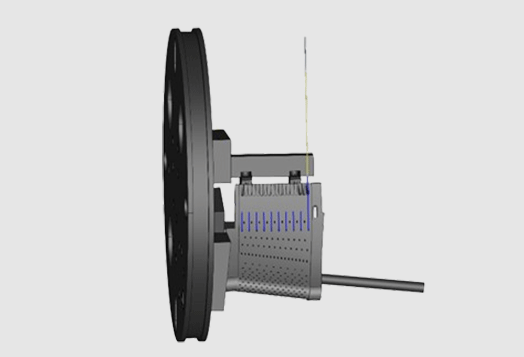

QJCAM.Inspection Feature measurement

QJCAM.Inspection has in-machine measurement function, planning measurement points on holes, axes, surfaces and other features by automatic or manual measurement, and the software will automatically generate the measurement path. The interference check function can calculate the interference between the parts and the probe to avoid the interference on the measurement path.

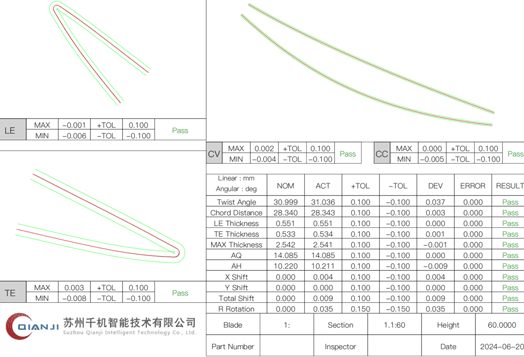

QJCAM.Inspection Feature evaluation

Through the obtained measurement point data, the software can perform GD&T evaluation, including the evaluation of diameter, distance, Angle, flatness, profile, position and other types of dimensions. The evaluation results can be output in PDF or customer template, and for profile detection, the software can output profile detection reports with contour graphics.

QJCAM.Inspection Self-cycle compensation

By associating the results of dimension evaluation, the software can compensate the out-of-tolerance dimensions in the automatic tool fill cycle. According to the conditional statement added by the user, if the size processing is qualified, it will jump out of the cycle, if it is not qualified, it is optional to alarm or add the tool compensation value for re-processing, and it will enter the measurement and evaluation node again after the processing is completed until the size processing is in place. The whole process does not need manual intervention to achieve full automatic execution.