Customer pain point:

Turbine parts have the characteristics of complex blade surface, high profile accuracy and surface quality requirements, and difficult to cut materials. The blade milling area of turbine parts is large, and it is limited by narrow flow path, and the tool handle and tool are long and rigid, which is easy to vibrate and let the tool occur in the milling process, reducing the service life of the tool. When machining thin-walled blades, the blades are prone to processing deformation, surface roughness, blade thickening and profile distortion, etc., which is difficult to ensure the design requirements and eventually lead to product scrap.

Solution & Value:

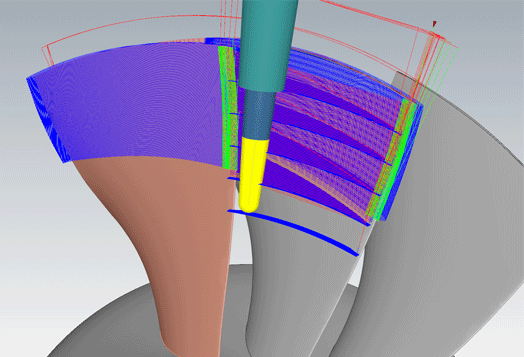

At present, for the numerical control programming of blade disk, impeller and blade ring parts, the team of Suzhou Qianzhineng Technology Co., Ltd. launched QJCAM.Turbo special programming module, combining processing experience and software research and development results to customize excellent process solutions for customers.

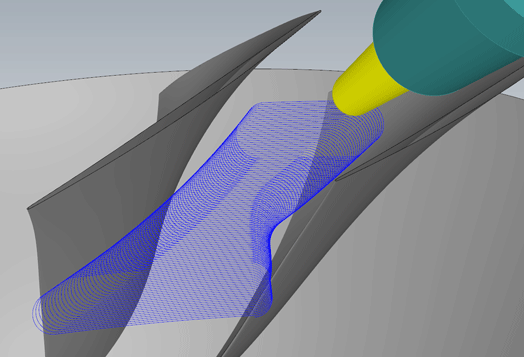

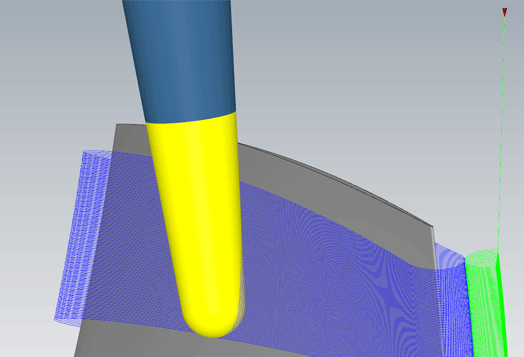

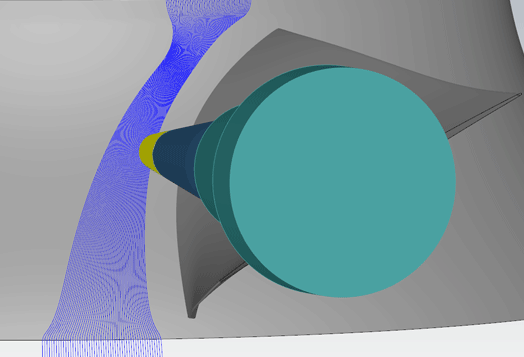

QJCAM.Turbo provides CAD assisted modeling, five-axis CNC programming, tool path simulation, post-processing and other functions. It is equipped with a machining strategy library covering the whole process of rough and finishing machining, and supports high-precision and efficient machining strategies such as cycloidal milling, mixed milling, combined milling and variable margin compensation.

Use QJCAM.Turbo NC programming software application advantages:

1. With variable allowance compensation function, the blade profile can be compensated by in-machine measurement or coordinate measurement results;

2. With coarse and fine combined milling, coarse and fine mixed milling function, effectively improve blade rigidity during blade finishing, reduce the negative impact of blade flutter on machining results.