Adaptive machining software is an intelligent software tool for aerospace parts repair in CNC machining scenarios, in order to improve the processing quality of parts and realize the closed-loop control of "online measurement-quality analysis-adaptive adjustment" of zero equipment.

Customer pain point:

Solution & Value:

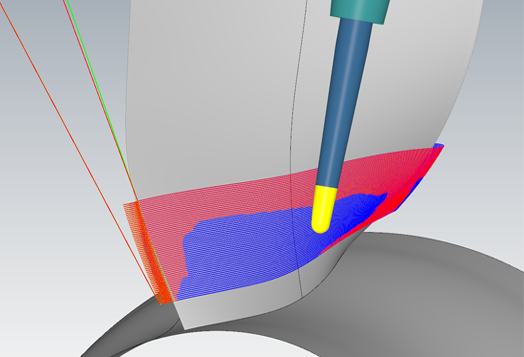

Aiming at the machining difficulties of linear friction welding blade disc, the team of Suzhou Qian Zhi Neng Technology Co., Ltd. proposed an adaptive machining scheme based on in-machine measurement and error compensation technology. The blade profile data was measured by a probe on the machine tool, and the deviation between position and profile was captured. The purpose of smooth connection between machining area and blade and qualified blade root size is achieved.

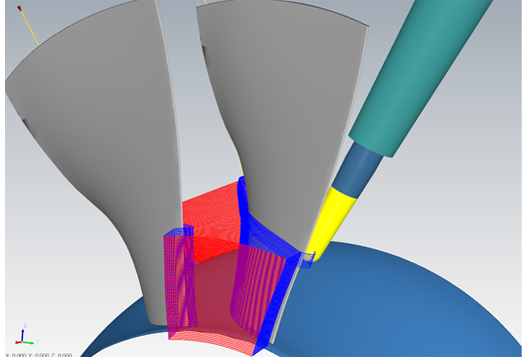

QJCAM.Turbo assists in generating machining paths

QJCAM.Turbo has a complete library of integral disk machining strategies. The machining tool path with uniform blade root allowance is generated by the layer milling and roughing of the runner, and the semi-finishing step of the blade is completed at the same time. The blade finishing tool path is used to generate the blade milling tool path, and the blade finishing step is completed.

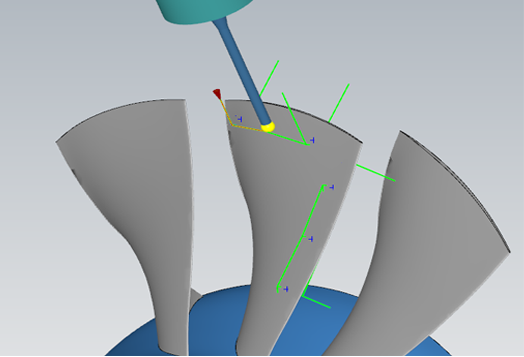

QJCAM.FIT Fast clamp parts alignment

Because there is no angular feature on the wheel, it is necessary to use QJCAM.Fit quick clamping for part alignment to avoid the situation of firing pins in the measurement process due to angular deviation. By placing points on the blade to measure, the best fitting calculation method is used to measure the data to ensure that the coordinate system of the measurement project coincides with the Angle of the part.

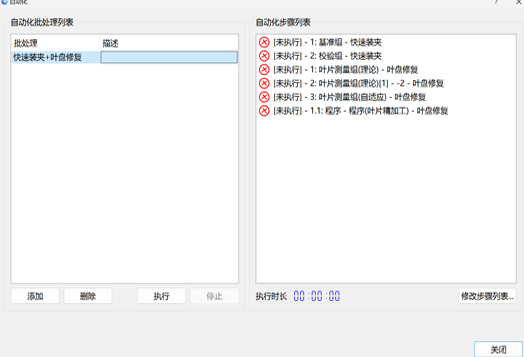

QJCAM.Fit automatic processing

The automation function of QJCAM.Fit can package the quick clamping and blade disc repair modules. Under the premise of establishing communication with the machine tool, the measurement program is automatically sent to the machine tool, the measurement is driven by the machine tool, the measurement results are returned, and the adaptive processing is completed. The whole process has no manual intervention, and the whole line of automatic production is realized.